- 01154014697

- 19 A Tanzem el-bekbashy st. sedibeshr, Alexandria, Egypt

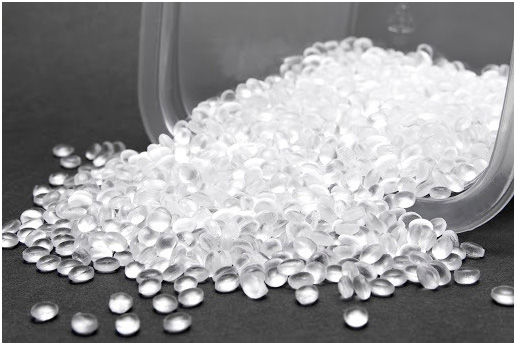

Polyethylene (PE)

Polyethylene (PE)

is a lightweight, durable thermoplastic with variable crystalline structure, Polyethylene is used in applications ranging for films, tubes, plastic parts, laminates, etc.

The most common types of polyethylene are Low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), High-density polyethylene (HDPE), etc.

(1) High-density polyethylene (HDPE):

Thermoplastic polymer made from petroleum. As one of the most versatile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping.

(2) Low-density polyethylene (LDPE):

Low-density polyethylene (LDPE) resins are used to produce a range of general-purpose and high-performance applications, which include blown and cast film, extrusion and coating, and rotational and injection molding.

(3) Linear low-density polyethylene (LLDPE):

Powder Rotational moulding:

Range is used for the manufacture of water tanks.